Understanding different kinds of Adjuvants and Surfactants

2024-11-25

Understanding Different Kinds of Adjuvants And Surfactants

Many herbicides and fungicides on the market require an adjuvant for optimum performance. But what are adjuvants and surfactants, and why are they important?

Generally, pesticides need to dissolve in water in order to apply them (“hydrophilic”). However, plant leaves are waxy, so they also need to be able to dissolve in wax (i.e. not dissolve in water, “hydrophobic”). This is a problem… As a result, most herbicides will require an adjuvant of some kind to help penetrate the leaf surface, though sometimes the adjuvant is built-in to the formulation (e.g. Horizon® NG, Axial® BIA).

The two main categories of adjuvants:

- Spray Modifiers- Modify the spray mixture. This includes things like anti-foam products, pH adjustors, drift reduction agents, etc.

- Spray Activators- Enhance the activity of the pesticide itself. These include things like surfactants, crop oil concentrates, ammonium fertilizers, spreader-stickers, and seed oils.

Note that adjuvants and surfactants are often used interchangeably, but they are actually different (a surfactant is just one type of adjuvant). The reality is that most adjuvants on the market are a combination of several of these things.

Within spray activators, there are a few categories:

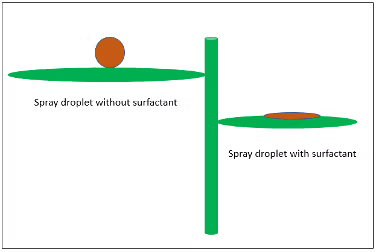

a) The surfaces of plant leaves tend to be covered in a rough, hairy, waxy layer when looked at very closely. When spray droplets hit them, they will sit on the plant leaf as a sphere, like a tiny basketball on the leaf so only a small amount of the herbicide gets into the plant. Surfactants lower the surface tension of the drop to flatten the droplet (turning the “basketball” into a “pancake”). This allows far more of the herbicide to contact the leaf and get into the weed.

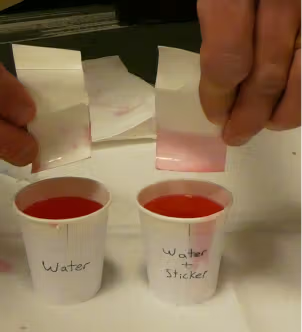

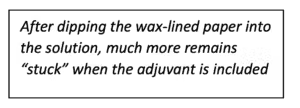

They can also include “stickers” that allow the droplet to remain on the leaf for longer to maximize absorption into the plant.

Surfactants are often divided into 3 types:

Non-ionic: Don’t have a charge. They tend to be more universal than the others so are most commonly used

Anionic: Have a negative charge. They are less common as they tend to be very specialized, but they are sometimes used with salt-based herbicides

Cationic: Have a positive charge. They are again very specialized. Sometimes they are used in glyphosate formulations.

b) Oil concentrates (e.g. crop oil concentrates, COC). These contain petroleum or vegetable-based oils, plusnon-ionic surfactants as a blend. They increase the herbicide penetration into the leaf, and are commonly used with post-emergent grass herbicides (often built into the formulation). These tend to be aggressive, so they can risk crop injury. Alwaysconsult the label before adding these to a product.

c) Nitrogen fertilizers. This is often AMS or UAN. There are a lot of water characteristics that can impact herbicide activity such as pH, water hardness, or dissolved solids. In particular, bicarbonate tends to tie up certain herbicides and prevent them from entering plants. AMS (ammonium sulfate) acts to prevent calcium cations from tying up the herbicide, and can also help some herbicides cross the plant cell membrane. For herbicides that are formulated as salts (e.g. BOA®), UAN is often required to get them into solution in a form that can get into the plant. It can enhance salt-formulated herbicides in this way, but does not improve calcium antagonism of glyphosate.

- Glyphosate is the most common herbicide that is often tied up by hard water. Adding AMS or another water conditioner can increase glyphosate activity as a result.

- Certain weeds build up ions on their leaf surface that can tie up the herbicide and prevent it from entering- AMS or UAN help the herbicide get into the plant in this case (hence the weed specific recommendations to add AMS such as adding AMS to glyphosate to control velvetleaf.

Some of the common adjuvants on the market in Western Canada are mixtures of various adjuvant types:

Merge® or ASSASSIN®: A 50/50 blend of crop oils and surfactants to increase the absorption of herbicides such as Ninja® or Samurai®

Agral® 90: A non-ionic surfactant that works well with many herbicides, fungicides, and insecticides to increase absorption to increase product efficacy

Score® or CHEM SPRAY®: 83% Crop oil and 17% surfactant specifically designed to maximize efficacy of Horizon® or AURORA® herbicide

Most grass weed herbicides require an adjuvant, though it is often built in. Broadleaf herbicides containing 2,4-D or MCPA often do not require additional adjuvants as their formulations act as surfactants themselves.

How Do I Know What Adjuvant To Use?

Adjuvants are often very specialized towards the pesticide they are being used with. Always follow the label directions for the specific adjuvant and rate to use, and never use adjuvants that are not specifically recommended. Using the incorrect adjuvant can result in:

- Crop injury

- Reduced performance of the product (e.g. too much surfactant can result in the droplets running off the leaves before being absorbed)

- Sprayer issues (plugging nozzles, residue build up in the tank, etc.)

- Mixing issues (products not going into solution in the tank)

The canola plant on the left was treated with an off-label adjuvant compared to the untreated leaf on the right

The same caution applies to micronutrients- often they are jar-tested with pesticides to ensure physical compatibility but are not tested to ensure they are safe to the crop or remain effective on the pest. AgraCity tests micronutrients with many pesticide mixtures, but it is impossible to test every possible combination. Always use caution when adding non-supported micronutrients to pesticide mixtures.

AgraCity has an extensive portfolio of adjuvants to maximize the efficacy of our herbicide products.